It is a recurring question that for some reason is repeated over time and for those who have doubts, we are going to try to provide solutions to the question of, why do memory chips not use thermal paste or TIM, either in GPU or in RAM? As we well know, these chips never go with these compounds, which always raises the question, let’s solve it.

Why companies like NVIDIA or AMD don’t put thermal pastes or TIM on their graphics cards if they have temperature problems. Why doesn’t any RAM manufacturer use TIM for their modules and heatsinks? It is something that is assumed in the industry, but few people question it.

NAND Flash is a problem to dissipate properly

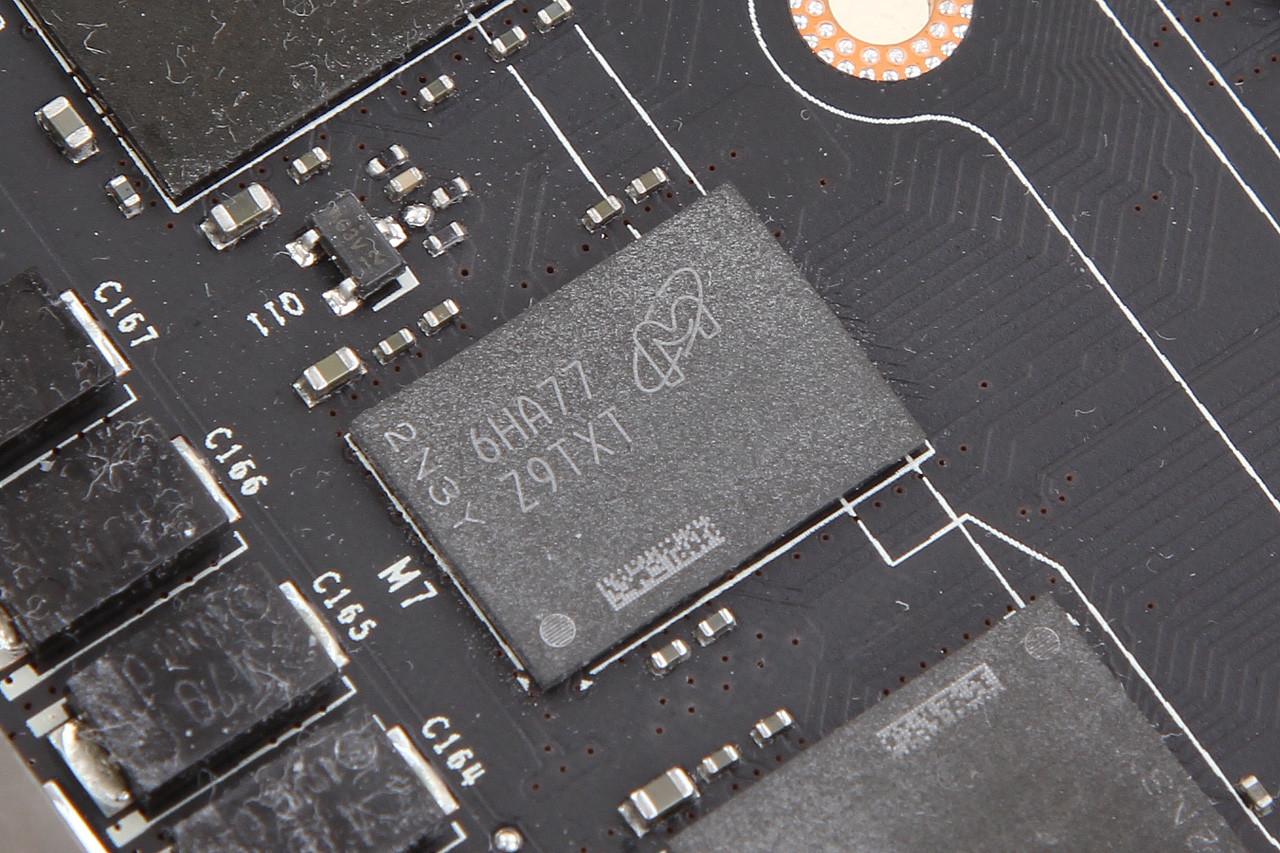

You have to start from the base to understand the whole problem and this is nothing more than how the NAND Flash are built, that is, how the memory chips that give life to all these components are built. Although their base materials are the same or very similar to those of a GPU, due to their construction, the NAND Flash are protected with a rough layer on the upper part that brings engineers headlong.

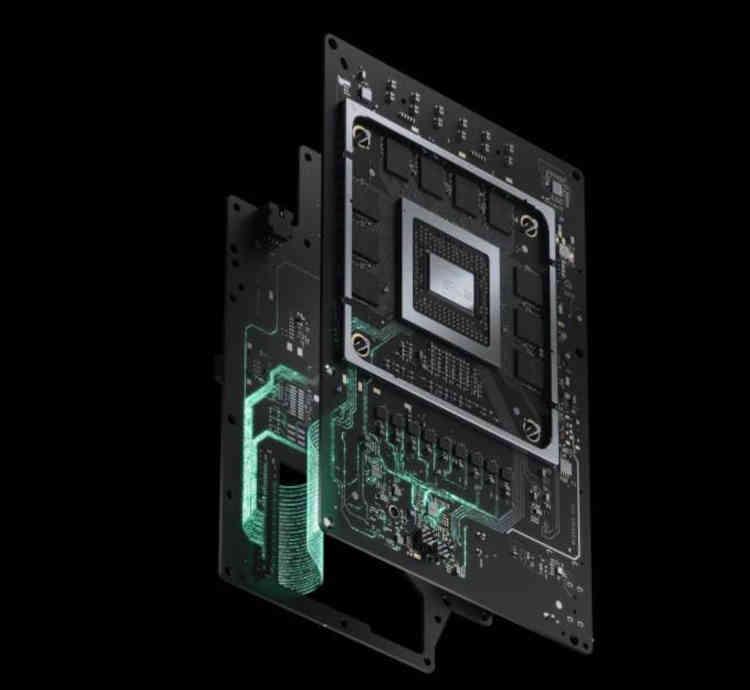

This layer is only to mark each silicon chip and prevent damage to its assembly and soldering, but it creates a series of problems that the industry solves in other cases such as HBM in a solomonic way: with high-performance thermal pads. .

The reason for not using TIMs is what is known as Manufacturing Tolerances, but what does this term mean? Well, basically it is a GAP that all the products have when they are manufactured or assembled with which the company has and that depending on the degree of perfection it will be higher or lower compared to the rest of the same pieces.

Chips are far from perfect

It must be understood that the distance between one chip and another in terms of height and dimensions, although it may seem minimal and ridiculous, represents a leap that no manufacturer wants to take on in costs to square the deficiencies.

In other words, it is very difficult for the industry for manufacturing tolerances to be so tight that they are reduced to the minimum in order to have adequate contact in all modules, be it an SSD, a GPU or a RAM.

To use a thermal paste or TIM, certain degrees of improvement are needed in several of the processes that would skyrocket costs, so thermal pads are used instead, which can be more or less dense and with a higher or lower transfer rate.

The thermal pads or thermal pads supply that GAP, that manufacturing tolerance in a cheap and optimal way. Even AMD in the Radeon VII used high-performance thermal pads in the die and HBM, so the industry moves in this direction. So it is practically impossible that in a tight period of time we will see some type of high or low performance NAND Flash with its heatsinks settled in thermal pastes or TIM.