3D printers have become one of the peripherals on everyone’s lips in recent years. Its enormous utility in many fields has made it an essential accessory in many fields. That is why we have thought that they deserve an article so that you can know how they work and how to use them with your PC in the best possible way.

3D printers began to be used for industrial needs, especially for the creation of parts for rapid prototypes. Thanks to this technology, it was possible to create unique pieces within a more complex model without the need to create special molds that also required the development of machines, a process that delayed the deployment of new products.

The first 3D printers were large and expensive to use, over time thanks to the improvement in technology the cost of 3D printing has been going down until it is possible to have them at home. Regarding the quality of the materials, these have been improving and now we have a large number of filaments to create all kinds of models easily. This has allowed small businesses to make their own 3D objects for various uses.

What types of 3D printers can we find?

There are different types of 3D printer, but the one we are going to focus on is FSM printers, which use thermoplastics to function and are the most common in homes. This type of printer makes use of PLA and ABS plastic filaments, although wood, cork and even coffee filaments have also been used.

SLA printers, on the other hand, are based on the use of resins, their finishes are much better and allow better prototyping. Today the SLA are widely used so that they do not require color and especially by fans of miniatures and modeling, who usually paint the models they use themselves.

SLA printers are often shut down by the noxious gases that the resin generates when it is heated. So they are much less safe and are not recommended for inexperienced hands.

Composition and operation of an FDM printer

The printing process on a 3D printer is as follows:

- The thermoplastic filament is loaded into the printer, which is fed into the extruder. Within which it is heated until it melts. The extruder is very similar in operation to a hot glue gun.

- The extruder is connected to a three-dimensional system that allows it to move in three different axes. From left to right, top to bottom, and near and far.

- The printer prints the object in layers, using the appropriate filament for each. Many times it will be necessary to change it in the middle of printing.

- The printing process is slow, since you have to wait for the material used to solidify, so some 3D printers usually have a small fan connected to the extruder.

- In order to make the physical model stronger, some printers tend to overfill some parts of the object.

The printer will print layer by layer until the object is finished, a process that depending on the printer we use can take hours.

How to get the models for our printer?

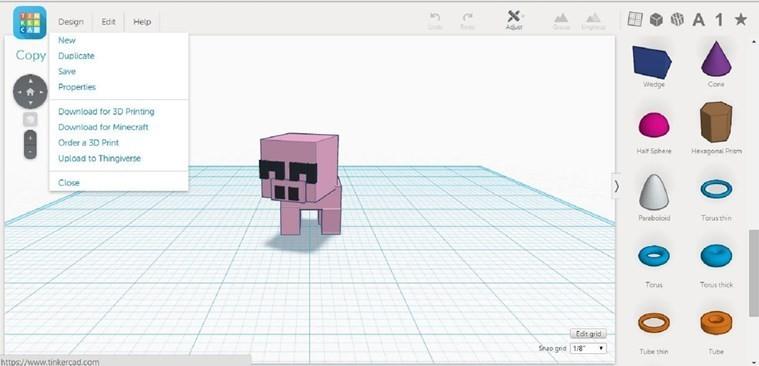

The first thing you will need is a CAD or computer-aided design program that allows you to model the object in 3D, you can choose the one you like the most and with which you feel most comfortable. We have cases like Blender, the famous AutoCAD used by architects and even Rhinoceros which is highly popular with jewelry designers, although you can also go for the easy yet simple TinkerCAD from Autodesk. All of them are valid so that you can create your objects and if you are interested you can share them on the network with other users so that they can print them

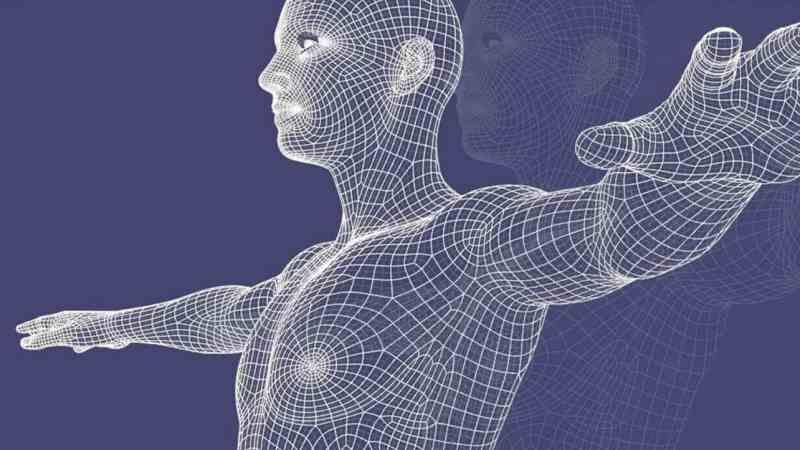

Another method that is used is 3D scanners, these are cameras that use infrared or light-time CCDs to measure the distance of each object with respect to the camera, in order to have a volumetric model of the object. It is a technique that is widely used in medicine to have 3D images, but because it is not based on polygons, but on voxels, it requires the transformation of the model to a polygonal or triangle-based one to be able to be manipulated later in a CAD program.

File formats for 3D printers

Let’s use the method we use, the most used file formats in 3D printing are the following:

- 3D Manufacturing Format (3MF): it is a format based on XML, and the standard of the 3MF consortium. It stores inside not only the shape data, but also the color and material used.

- Additive Manufacturing File (AMF): another XML format with characteristics similar to 3MF, since it also stores shape, material and color as information.

- Object file format (OBJ): Used as a compatible image format between various 3D editors, but not this

These formats are not enough to be able to print an object on a 3D printer, but it is necessary to use Slicer programs, about which we will talk next.

What is Slicing for 3D Printing?

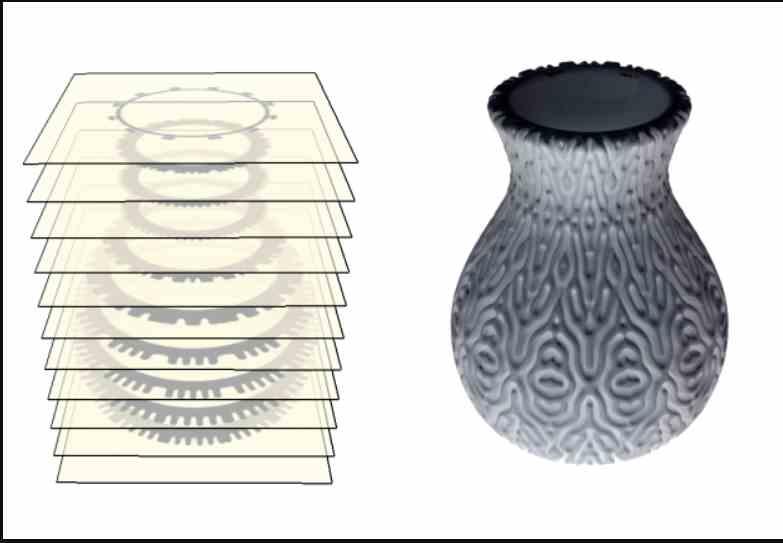

3D printers print the objects in layers, printing each one on top of the other in a process where each time the real model is gaining more height. Contrary to other methods of printing objects we are not talking about casting an object in a mold or sculpting on a stone.

This makes it necessary to use software that takes the original model and converts it into a file format where it is defined how each of the layers that make up the object to be printed are. We call the process Slicing and this type of application Slicers.

Not only do they transform the model into a series of layers that the 3D printer can use, but in many cases they allow us to adjust the height of each layer, the filling density, and even create supports so that the 3D structure supports itself by if necessary in the middle of printing. So this type of software is also part of the creative process to be able to obtain the best possible piece.

How do I communicate my 3D printer with the PC?

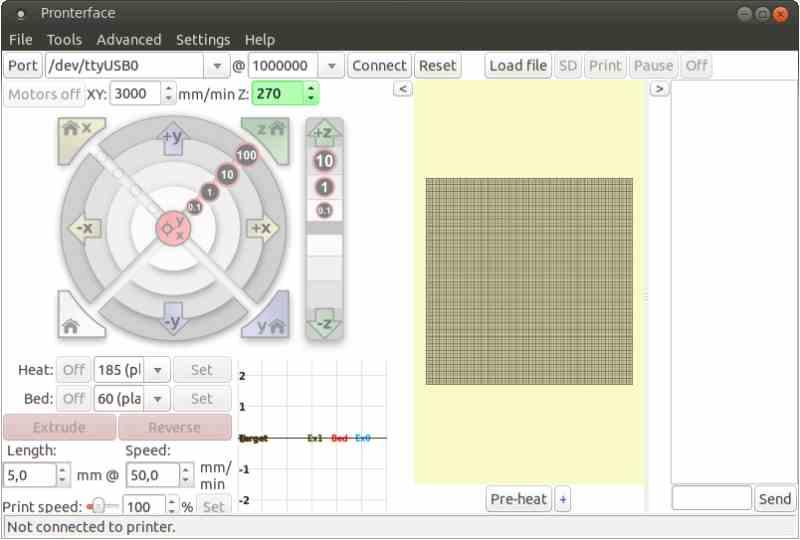

Well, in the same way as other printers, you can use a USB connection, make use of an SD card to store the files to print and even via Wi-Fi. So its installation is the same as that of any other peripheral.

But as with conventional printers, 3D printers require software to control 3D printing, we recommend Pronterface, which allows us to control the different aspects of it in a direct and comfortable way. Apart from being compatible with Windows, Mac and Linux.

With this you should already be able to print your models on your 3D printer.