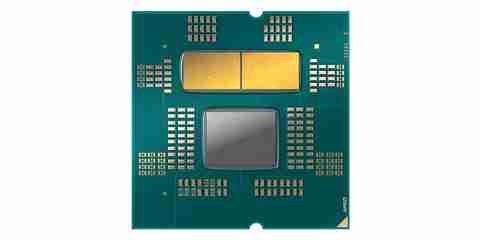

In an unusual turn of events, an undisclosed overclocker has leaked a very interesting photo that explains several important points with AMD‘s new Ryzen 7000. This photograph reveals the IHS that AMD has put on its new processors, where in a clear delid what we see is the inside of it and here comes the worrying part. These Ryzen 7000 processors could have temperature issues.

The leak is partly a surprise and partly not. The part that is not surprising is because of the shape of the IHS and its dimensions, since we had a very advanced idea of this because of everything that has already been revealed, but… The part that is surprising is for the worse.

The temperature problems of the Ryzen 7000

The problem that this IHS has and that will determine the thermal performance of these processors is mainly one: its thickness. The image shows three different dies, the I/O die and the two core chiplets, which we will talk about later.

But although they are all soldered to the IHS using gold foil, the problem of thickness goes unnoticed by almost everyone. And it is that more material, be it copper or graphene , implies greater thermal resistance to the passage of heat from the dies to the heat sink or block.

For us to understand this, reducing just 1 mm in the die in terms of its height can change the temperature between 2 and 3 degrees Celsius. So let’s imagine adding almost 2mm on a piece of copper of this gauge. But in addition to all this, there is another factor to take into account and that we already sensed at the time and it has to do with the distances in millimeters of the AMD layout for these processors.

The distance between dies, another thermal problem?

AMD has a disadvantage against Intel due to latencies between cores, caches and access times compared to RAM. It is inherent to the MCM architecture that AMD uses and that is why Lisa Su has reduced the distance between dies to a minimum, to only 1 millimeter .

The advantage is obvious, the disadvantage is that as you can see and we already intuited at the time, the welds are together, almost joined, and this will surely result in a higher temperature for the cores.

In addition, there is a very important detail that is not being discussed: the connection points of the IHS to the PCB or substrate. We perfectly see how AMD is going to cut back on the silicone it uses thanks to an IHS with a peculiar shape with specific gluing points. Therefore, it is logical to use specific silicone points that ensure the non-mobility of the IHS and the non-breakage of the weld, thereby allowing thermal bridges due to micro-cracks in it (the latter remains to be seen in the image).

What’s new then? One silicone point is missing from all those available, and as we thought it is right at the point closest to the two dies of Cores. Why is this done? It’s a mistake? No way. It is simply a thermal outlet to the outside. Leaving that point without silicone allows a tiny space where the heat pressure produced by the three chiplets escapes and regulates itself.

It is strategically designed so that this happens at the point of greatest heat and thermal load, so without a doubt we can talk about serious temperature problems of these chips, even though the new control algorithms will alleviate it by lowering frequencies as is already happening in the current Zen 3. Increasing the PPT is not going to help either and evidence and support everything said, now we just need to see if we are indeed right and above all, to what extent we are right.