If the WiFi coverage does not reach certain rooms in your home or work center, the normal thing is to go to solutions such as those that WiFi repeaters or PLC technology can offer. These solutions have been added, for some time, the plastic optical fiber or POF.

The operation of fiber optics is based on light as a means of data transmission . It is a medium through which photoelectric pulses travel. For this, conductors generally made of glass are used if a large bandwidth is needed and of other materials derived from plastic for more basic needs. A light signal travels through these conductors from one end of the fiber cable to the other. This light signal is usually generated by an infrared laser or a high-power LED that emits pulses of light to transmit the data.

Characteristics

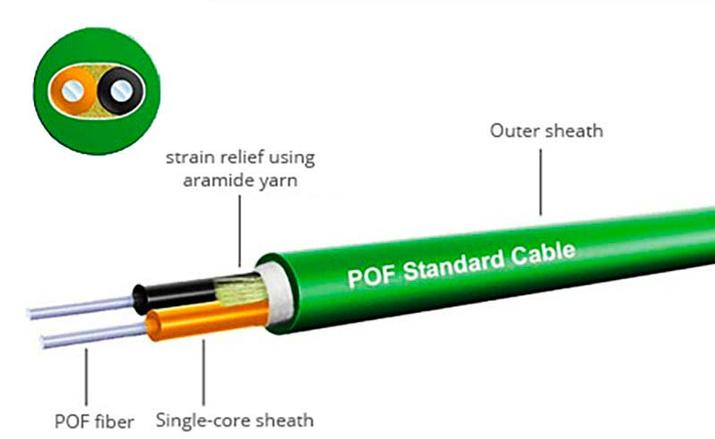

Plastic or POF optical fiber is made of plastic, specifically a polymethylmethacrylate core through which data travels by means of electrical impulses. The cable also has a coating also based on plastic material.

This type of fiber uses a much thicker core than fiberglass, allocating almost 95% of the cable section to transmitting light. These are cables with diameters around 2 mm and with cores between 0.25 and 1 mm in diameter. The simple fact of using materials of lower cost than fiberglass means that this type of fiber is slower.

One of the fundamental differences of plastic fiber with respect to fiberglass is that it supports and is more flexible . These cables can come to admit a curvature of 20 mm radius, that is, we could get to make a circumference with a 4 cm cable without it breaking and continuing to be functional. This is a clear advantage over the one based on silicon dioxide glass, which admits much less flexibility in addition to being much more fragile.

Advantages of using plastic fiber

After knowing a little about the main characteristics of plastic fiber, it is time to find out what advantages it can have over glass fiber optics or other means of communication.

- The manufacturing cost is considerably lower than that of fiberglass.

- It can work much better. This means that we will be able to cut it to size directly on the work field without needing high precision elements.

- Allows less attenuation . Fiber based on plastic material has a lower signal absorption and dispersion coefficient because it has fewer impurities than glass.

- Its flexibility. It allows to have cables that are thinner than ethernet and easier to handle than coaxial ones. What allows the installation in our home without major problems.

- It is immune to electrical noise . As it is based on photoelectric pulses, it has immunity against interference from neighboring electrical cables.

Like everything in life, plastic fiber not only offers advantages. Some of the disadvantages that it can have is that it does not withstand humidity or corrosion as well as fiberglass does. Furthermore, this type of fiber is not capable of retransmitting infrared light, which means that its capacity and bandwidth are not as high as fiberglass.