It will not be the first or the second time that we will encounter the problem of having a screw in our tower that we cannot remove. Unfortunately, it is more common than it seems, so we have decided to help you with some techniques or solutions to try to remove that rebellious screw and make it stop being so. Ready? Well let’s get started

There are no miraculous results, a stuck screw, for whatever reason, only has two solutions in a PC chassis: either it ends up coming out or we will have lost that thread forever. The problem that our sector entails is that in many cases the screws are made of plastic, generally ABS, so destroying them will be very easy.

Try these tricks that can fix the problem

The tricks that we are going to see range from some where you do not have to spend a single penny to those that you have to leave good money to get that rebellious screw out. So having said this and keeping it in mind, we must understand that some of them cannot be carried out by the screw area, but perhaps they can be carried out partially.

The most basic

Use the right screwdriver

It seems the most obvious thing in the world, but nothing could be further from the truth: most users have at most 3 screwdrivers for all types of screws. The problem is that depending on which screws the head of the same has nothing to do with what we need, neither in dimensions nor in depth.

The first recommendation is to acquire once and for all a specific screwdriver kit, type iFixit with one of its kits, which are from 15 euros to the most advanced of almost 100 euros.

If we do not want to spend money, the ideal is that we do not use a star head for a star screw if it is too big for the screw head. Otherwise, it is better to use one with a smaller blade and, based on small blows, try to force the rotation of the screw. It will take time and the blows should be dry, not very strong and accurate, but it usually works if we have patience.

Elastic rubber

Another solution would be to use an elastic band like those used by postmen to group the letters, since being made of a very flexible material if we insert it into the screw head and then use a screwdriver, the rubber will enter the slits and allow us to have more traction when it is not the perfect metric for the screw in question.

There is no more science, but you will have to be patient and use several pieces of the rubber to remove the screw as such.

Olive oil

Another of the most basic tricks and assuming that we do not have a professional mineral oil at hand is to simply use a couple of drops of olive oil at the base of the screw to soak it inside its thread and make it move better when we try. remove it with the screwdriver.

The most common

Multipurpose oils

There is not much to comment here beyond well-tested products like WD40 or similar. The trick here is to place the screw perpendicular to the floor or table, that is, at 90 degrees from the horizontal, apply the oil in its right amount and being very accurate and above all, leave it to act for a few hours so that it penetrates the holes.

It is more than likely that if we have the specific screwdriver, this method will be very useful, because we will remove the screw effortlessly.

Cold effect loosening oils

It seems like a no-brainer, but the truth is that even in nylon screws, be it the plastic thread or another material, the reality is that combining a multipurpose oil with a cold-effect loosening oil plus a suitable screwdriver, is the perfect union for do not damage the box or product in question.

This type of oil comes out at a very cold temperature and you have to be careful where it is applied so as not to damage other components, you have to be precise in its application, but they are tremendously useful, especially if either of the two materials is metallic. In addition, they are usually cheap and one bottle is generous for several applications.

The most extreme

Pressure or impact screwdriver

It is a very curious screwdriver, since we have to hit it at the opposite end of the tip and with it and through its system it multiplies the effect and force of the blow, transforming it into turning force.

That is, the stronger we hit it, the more turning force it makes. Logically we must have the exact head at the head of the screw to exert the greatest possible force, and also, we have to be very precise with the blow so that the screwdriver does not move.

The second problem is that this is not useful if the screw is not metallic, since with such force exerted we can easily pass the screw head, so it is a double-edged sword.

Heat with heat gun

It is a very aggressive method and above all very delicate, since it involves heating the screw and the thread with a heat gun so that they expand a little. A powerful heat gun is not necessary, it can even be hand-held, since we barely have to get between 60 and 70 degrees in both components.

The problem is that, logically, we need both to be metallic, because if not what we will have will be a beautiful seal between the two because they will melt to a greater or lesser extent.

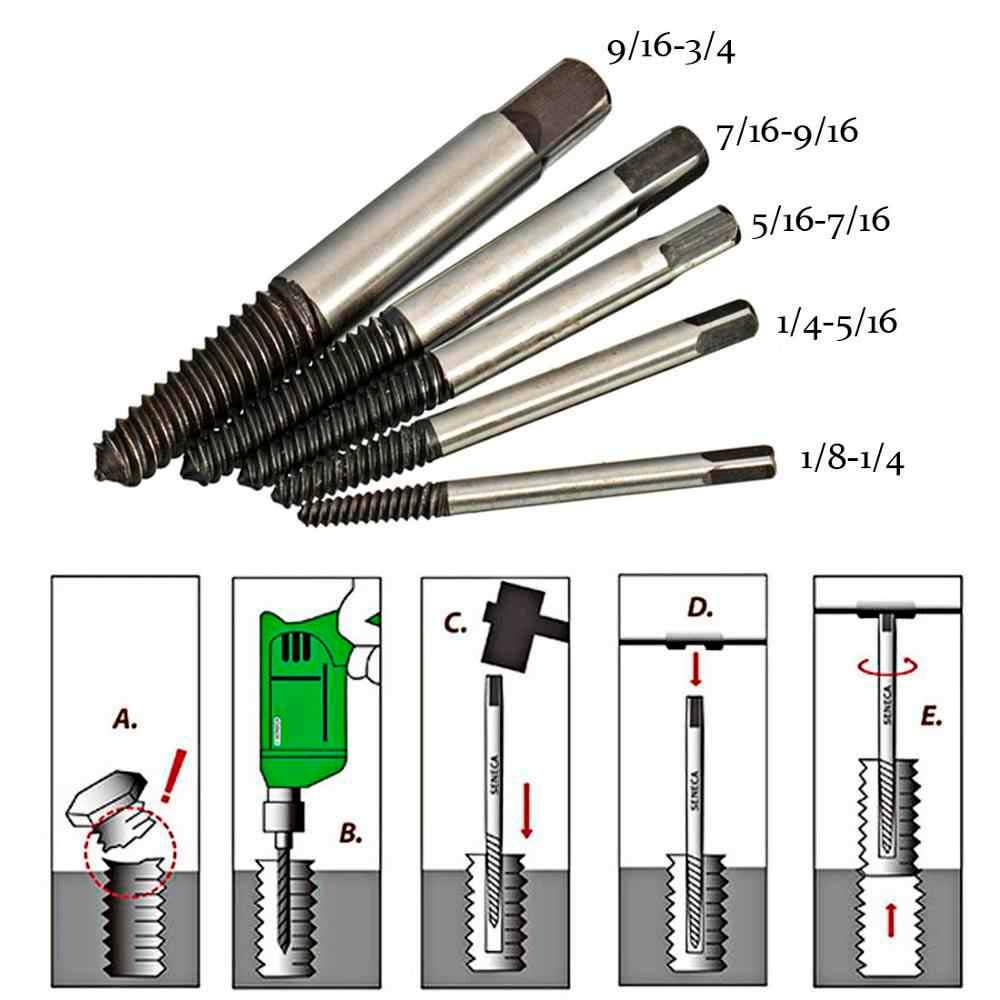

Screw extractor

It is the last possible solution, since it involves a bit with its corresponding Dremel or drill. It involves taking a metal drill bit (if the screw is plastic) or a high-speed steel (if the screw is metal) with a smaller diameter than the screw and drilling it vertically to the end of it.

Then and once the hole is made, a screw extractor must be installed, which must be very specific given the size of the hole, we will put it in the center of the screw and with a spanner or any tool that we can turn the extractor to insert it into the screw.

Sometimes it is not necessary to drill the entire screw, but simply its mouth, but to extract it by turning it, we will have to be very careful.