The emergence of 3D technology has led to a revolution in this field. Anyone can buy a 3D printer and make practically anything you want with it.

There are also many companies that take advantage of 3D printing technology to create tools and mechanisms that make their work easier and faster.

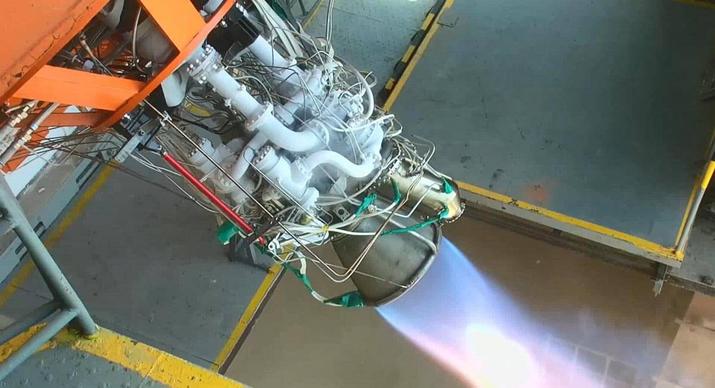

This is the case of the Australian company SPEE3D specialized in 3D printers that wants to innovate when it comes to manufacturing rocket engines that will go into space and wants to manufacture these using this technology, which would also lower many costs.

A subsidized project

This company has received an amount close to a million and a half euros thanks to various grants, which will allow it to carry out this ambitious idea. This project is called SPAC3D and will be applied only in Australian territory, although the objective is to expand the use of these engines throughout the world.

The subsidies have been granted in large part by the Australian government as the country wants to become a nation that in this sector is at a very high level and that can compete without problem with other world powers in this sector.

The company will collaborate with other companies on the continent to develop these engines made with 3D printers and which will be sold in the future to all those space companies that want to use these propellants.

The problem they face is the production speed of these engines. There is already history of other companies that have manufactured the same product in a few hours and at a low cost, but SPEE3D still has to optimize its technology to manufacture engines that give optimal performance and that it is economically to manufacture them, unlike the rest of current companies .

A project with a great future

This company stands as the main supplier of space rocket engines for all companies working in the space industry in Australia. Many jobs are being created that allow SPEE3D to meet its forecasts and cover all needs.

The use of 3D printing technology for this type of project implies that there are no limits when trying to collaborate with other companies to try to get a cheaper product, in less time and that can also work the same or better than something that has been manufactured with traditional methods.

After receiving approval to do its project, the company will have to carry out many tests to optimize the performance of the rockets so that they can be used in the future of space missions.